Ingenious solutions provide better overall economy

| Flexofoil® ceramic wear elements is our most succesful product within our range. Flexofoil® ceramic wear blades and covers stands up to the high demands andexpectations for ceramic wear elements. |

There are big differences between Flexofoil® ceramic wear elements compared to the "traditional" cintered ceramic elements:

- Flexofoil® ceramic wear elements has no segments. It´s buildt up in one length, (up to 10800 mm / 425"), across the machine width.

- Thanks to the construction, Flexofoil® are more resistent to ie. thermoshocks with less risk for cracks to follow.

- Flexofoil® can be treated more "rough" without risk for damage, compared to a "piano" segmented blade, which is a big advantage during maintenance and service.

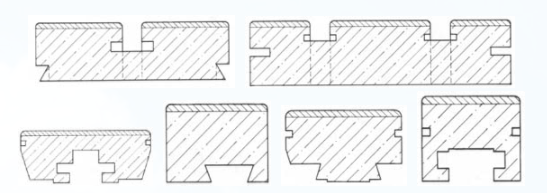

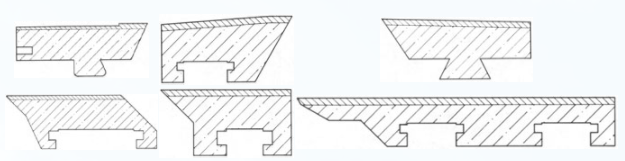

- It is possible to order Flexofoil® wear elements, blades and covers in almost any shapes and forms which are used in the paper machines today.

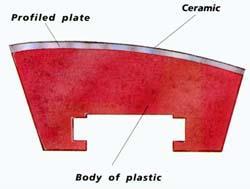

Flexofoil® is a combination of materials. It is based on a body of HDPE-plastic, a stainless steel plate (316L) and at the top a coated ceramic wear layer grinted/polished to fine surface smoothness.

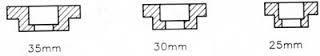

- Fit to all fixing alternatives available in the market, such as dovetail or T-bar

- Since there is no joints between the profile plates and the outher layer, the risk for break of fabrics and wires is eliminated

- The smooth finish of the coating results in a low wear of fabrics and wire as well as low energy consumption

- Vibration problems are minimal

- Possibility to install measuring transmitter of friction temperature